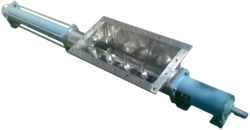

A line of Sanitary Progressive Cavity Pumps designed for handling Food Products, Pharmaceuticals, and Cosmetics where ever bacteria and contamination must be avoided, or where frequent clean-up is required due to product and / or process changes. They meet national & international sanitation requirements. We not only supply pumps that are CIP and SIP capable but we also offer planning and designing for your entire pumping applications.

Execution:

- Long life closed or open Cardon Joints / Pin Joints.

- Reversible flow direction.

- Suction / delivery standard connections or IDF & option SMS, DIN, JIS Clamp & Ferrule Type.

- Housing in AISI 304, AISI 316 & AISI 316L. The surface is smooth, eliminating product retaining pockets.

- Rotor / Shaft & Rotating Parts in AISI 304, AISI 316 & AISI 316L

- Torsion Free Moulded to Stainless Steel / M.S. Tube Rubber Stator in NCR Food Grade Nitrile, EPDM in white & black colour elastomers.

- Shaft Sealing by Stuffing Box food grade Gland Packed / Mechanical Seal

Specifications:

| Capacity |

Up to 50 m/hr. |

| Pressure Stages |

6, 12, 18 & 24 Bar |

| Temperature |

Up to 150 C / 302 F |

| Viscosity |

Up to 30,000 cst |

| Solid Handling Capability |

Up to 12% |

Applications:

Broken cheese in whey, cocoa chocolate masses, colors & paints, creams, curd, egg liqueur, extract of malt, fruit juices, fruit mashes, grease & oils, honey, hops mash, ice cream, jam, liver mash, mayonnaise, meat & herring salads, milk & condensed milk, mustard mash, pastes, pasty fruit, rasped horse-radish, sausage masses, shampoo, soaps, soft cheese, spinach, tomato pulp, tooth paste, vegetable pulps, yeast paste, yolk and white of eggs etc.